Double Jacketed Dish Bottom Vessel

The Double Jacketed Dish Bottom “A” Vessel is engineered for precise and uniform temperature control, making it an excellent choice for temperature-sensitive and shear-sensitive cell lines. Its double-jacketed design supports accurate heating and cooling through circulating media, providing a stable thermal environment essential for delicate cultivation processes.

The smooth, dish-shaped bottom enhances mixing performance while minimizing dead volume, and for particularly fragile cells, a pitched-blade impeller is recommended to ensure gentle, efficient agitation. Fully compatible with Winpact controllers, probes, impellers, and gas-handling components, the “A” Vessel delivers reliable, high-quality performance for advanced fermentation and cell-culture applications.

Single Wall Dish Bottom Vessel with optional Heating Blanket

The Single Wall Dish Bottom “B” Vessel combines efficient temperature control with a geometry optimized for superior mixing. Equipped with an internal cooling coil, it provides precise thermal regulation, while compatibility with an external heating blanket enables accurate heating without the need for a jacketed design. This combination makes the “B” Vessel especially effective for photo-sensitive or photo-inhibited cultivations that require tightly controlled temperature conditions.

The dish-shaped bottom ensures smooth fluid circulation and eliminates dead volume, promoting uniform mixing and consistent culture conditions throughout the vessel. Fully compatible with Winpact impellers, probes, and sparging components, the “B” Vessel offers a flexible, reliable solution for a wide range of fermentation and cell-culture applications that demand stability, precision, and efficient heat exchange.

Air Lifter Vessel

The Air Lifter “C” Vessel features a unique agitator-free design that provides gentle, gas-driven mixing—ideal for cell lines and organisms that require circulation without the shear stress associated with traditional impellers. Using controlled aeration rather than mechanical agitation, the system helps maintain cell morphology while still achieving effective mass transfer. An integrated micro-sparger and an adjustable internal draft tube work together to promote efficient liquid circulation, resulting in high aeration performance and uniform culture conditions throughout the vessel.

One of the standout capabilities of the Air Lifter system is its ability to function as a photobioreactor when paired with an optional lighting module. This enables photosynthetic reactions for plant cells, algae, and other photo-dependent organisms. The “C” Vessel is available in both single-wall configurations—ideal for processes not requiring temperature control—and double-jacketed options for applications that demand precise thermal regulation. This versatility makes the Air Lifter “C” Vessel a powerful solution for low-shear, high-aeration bioprocessing and photobioreactor research.

Single Wall Plain Bottom Vessel with Heating Base Unit

The Single Wall Plain Bottom “D” Vessel is a dependable, easy-to-use option designed for routine microbial culture and general laboratory fermentation work. Its straightforward flat-bottom geometry provides predictable mixing characteristics, making it well suited for day-to-day processes and strains that perform reliably under standard cultivation conditions. Built with durable stainless-steel support rods and a reinforced base plate, the “D” Vessel is engineered to withstand frequent handling and long-term laboratory use.

When paired with the external Winpact heating base, the “D” Vessel offers efficient thermal transfer and stable temperature regulation up to 90 °C—delivering consistent performance without the complexity of a jacketed design. This makes the FS-V-D series an excellent choice for dominant microbial strains, basic fermentation workflows, educational settings, or any application requiring a robust, cost-effective vessel that balances simplicity with reliable heating and control.

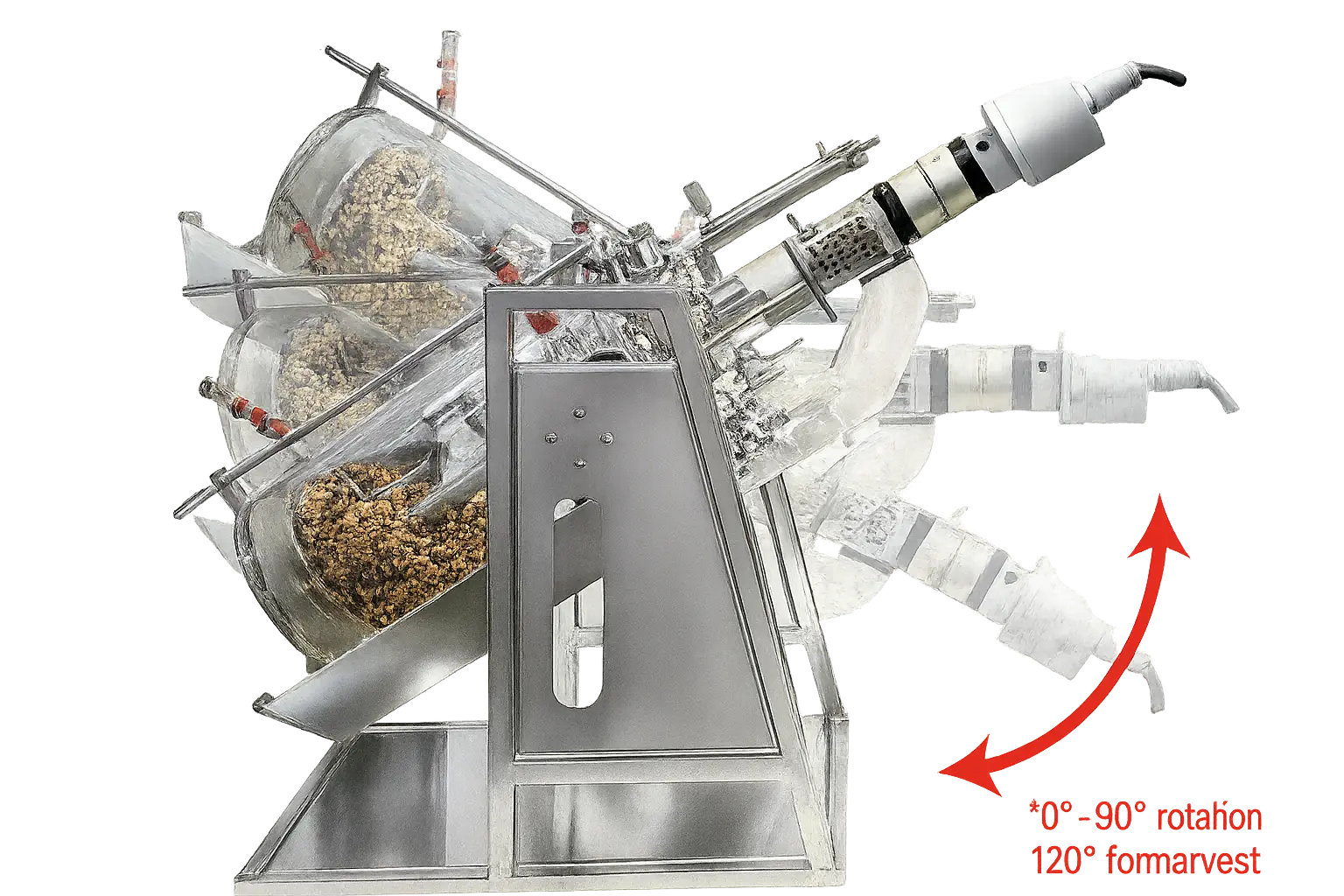

Solid State Vessel

Solid-state fermentation (SSF) is widely used for the production of enzymes, antibiotics, biofuels, organic acids, and other high-value bioproducts across the food, pharmaceutical, cosmetic, and biotechnology industries. SSF requires low-moisture cultivation conditions ideal for fungi, molds, filamentous organisms, and select bacterial strains. The Winpact Solid State Vessel is purpose-built for these applications, offering excellent environmental stability and surface-based growth conditions for laboratory-scale research.

Designed for precision and ease of use, the Winpact Solid State Fermentation System features a 10.4" color touchscreen, an intuitive Linux-based interface, and four built-in peristaltic pumps for controlled substrate or reagent delivery. An automatic vessel-angle control mechanism ensures outstanding mixing efficiency for solid-state materials, supporting both aerobic and anaerobic workflows. Three impeller options—broken, anchor, and spiral—provide flexibility for different substrate types and process requirements, making this vessel a powerful tool for advanced SSF research and development.